In industrial and hydraulic systems, efficiency and safety are paramount. The ability to quickly and securely connect and disconnect fluid lines can make a significant difference in operational uptime, maintenance speed, and workplace safety. This is where the Quick Release Coupling, or QRC couplings, comes into play. These small but mighty components are the unsung heroes of countless applications, from heavy-duty construction machinery to delicate manufacturing processes.

This guide will explore everything you need to know about these essential connectors. We will dive into what a QRC coupling is, explore the different types available, and discuss their applications. We will also highlight what to look for when choosing a manufacturer and introduce a key player in the Indian market. Whether you’re an engineer, a maintenance technician, or a procurement manager, understanding the nuances of the quick coupler will help you make more informed decisions for your operations.

What is a QRC Couplings?

A QRC coupling, also known as a quick connect coupling or quick coupler, is a mechanical device used to join or separate fluid lines rapidly and without the use of tools. Its primary function is to provide a fast, reliable, and leak-proof connection that can be engaged or disengaged with a simple push, pull, or twist motion.

The design typically consists of two parts: a male plug (or nipple) and a female socket (or coupler). The socket contains a valve mechanism that automatically shuts off the flow of fluid when the coupling is disconnected, preventing spills and loss of pressure. The plug also often contains a valve to seal the other end of the line. This ingenious design eliminates the need to drain systems or shut down main lines for simple component changes or maintenance tasks, saving valuable time and resources.

Exploring the QRC Hydraulic Coupling

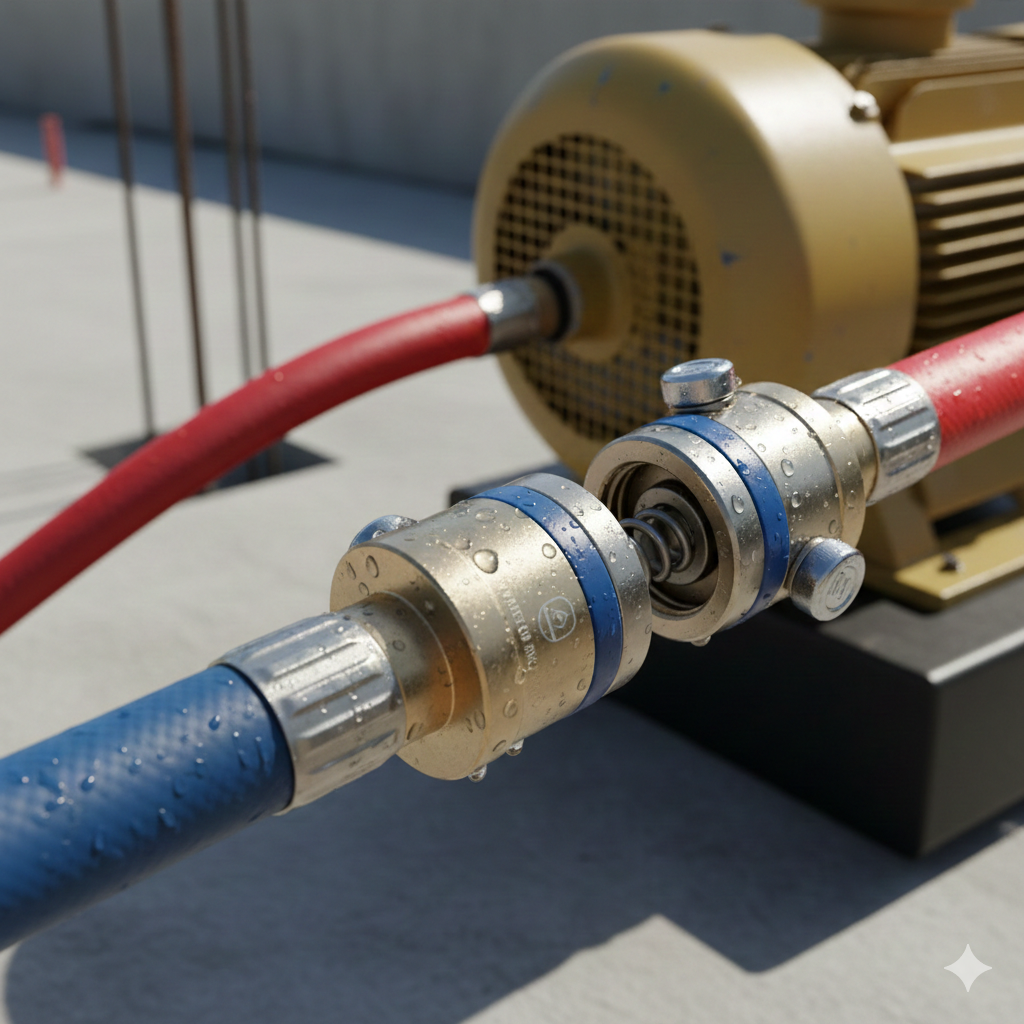

When dealing with high-pressure systems, the QRC hydraulic coupling is the component of choice. These specialized couplings are engineered to withstand the extreme pressures inherent in hydraulic circuits, which are common in construction equipment, manufacturing machinery, and agricultural vehicles.

A standard hydraulic quick release coupling is built from robust materials like high-strength carbon steel, stainless steel, or brass to handle pressures that can exceed 10,000 PSI. They feature secure locking mechanisms, such as ball locks or threaded sleeves, to prevent accidental disconnection under pressure, which could be catastrophic.

Key features of a hydraulic quick release coupling include:

- High-Pressure Rating: Designed specifically for the demands of hydraulic fluids like oil.

- Durability: Constructed from materials that resist wear, corrosion, and physical impact.

- Safety: Features like locking sleeves prevent dangerous disconnections.

- Minimal Spillage: The valving system ensures little to no fluid is lost during connection or disconnection.

These features make them indispensable in applications where hydraulic tools are frequently swapped out, such as on an excavator changing from a bucket to a hydraulic hammer.

Beyond Hydraulics: Quick Release Coupling for Water

While hydraulic applications are common, the use of a quick release coupling for water is just as widespread, though the requirements differ. These couplings are essential in agricultural irrigation, industrial cleaning, food and beverage processing, and even simple garden hoses.

Unlike their hydraulic counterparts, couplings for water applications often prioritize flow rate and corrosion resistance over extreme pressure handling. They are frequently made from materials like stainless steel, brass, or high-grade plastics to prevent rust and contamination, especially in potable water or food-grade applications. The QRC connector for water ensures a swift and drip-free connection, which is crucial for maintaining a clean work environment and conserving water.

Navigating the QRC Couplings Catalogue

For anyone sourcing these components, a QRC coupling catalogue is an invaluable resource. This document, provided by manufacturers, is more than just a list of products. It is a detailed technical guide that helps engineers and buyers select the perfect coupling for their specific needs.

A comprehensive catalogue typically includes:

- Series and Types: Different coupling designs (e.g., ISO A, ISO B, Flat Face).

- Material Specifications: Details on body materials (steel, brass, stainless steel) and seal materials (NBR, FKM, EPDM).

- Pressure Ratings: Maximum working pressure for each coupling size.

- Flow Rates: Data on the volume of fluid that can pass through the coupling.

- Temperature Ranges: The operating temperature limits for the coupling and its seals.

- Dimensions and Thread Types: Detailed schematics with measurements and available thread standards (NPT, BSP, ORFS).

- Interchangeability Information: Notes on which industry standards (like ISO 7241) the couplings meet, ensuring they can be interchanged with other brands.

Carefully reviewing a QRC coupling catalogue ensures that you choose a connector that not only fits physically but also performs reliably and safely under your specific operational conditions.

Choosing the Right QRC Coupling Manufacturers

The market is filled with QRC couplings manufacturers, but not all are created equal. The quality of a coupling directly impacts the safety and efficiency of your entire system. A failing coupling can lead to costly downtime, hazardous leaks, and potential injuries.

When evaluating manufacturers, consider the following criteria:

- Material Quality and Sourcing: Reputable manufacturers use high-grade, traceable raw materials to ensure strength and durability.

- Manufacturing Precision: Tight tolerances are crucial for a leak-proof seal and smooth operation. Look for manufacturers who invest in advanced CNC machining.

- Testing and Certification: The best manufacturers conduct rigorous testing for pressure, burst, endurance, and flow. Certifications like ISO 9001 indicate a commitment to quality management.

- Product Range and Customization: A broad product line shows expertise across various applications. The ability to offer custom solutions is also a sign of a capable manufacturer.

- Technical Support and Expertise: A good supplier acts as a partner, offering expert advice to help you select the right product for your application.

A Spotlight on Expertise: Rubber Hose India

When discussing reputable manufacturers in the Indian subcontinent, it’s impossible not to mention Rubber Hose India. With years of experience in the fluid power industry, Rubber Hose India has established itself as a premier supplier and manufacturer of a wide range of hydraulic and industrial components, including a comprehensive line of QRC couplings.

What sets Rubber Hose India apart is its deep understanding of the diverse needs of Indian industries. They provide robust and reliable quick connect coupling solutions tailored for everything from rugged agricultural machinery to sophisticated manufacturing plants. Their focus on quality control and customer satisfaction has made them a trusted partner for businesses seeking performance and durability.

Rubber Hose India offers an extensive selection that covers various types of QRC couplings, including those compliant with international standards. Their expertise ensures that customers receive not just a product, but a solution that is perfectly matched to their application, backed by solid technical support and a commitment to excellence. For those operating in the region, they are a go-to source for high-quality fluid connection solutions.

Conclusion

The humble QRC coupling is a cornerstone of modern fluid systems. From high-pressure hydraulic circuits to simple water lines, this versatile QRC connector provides the speed, safety, and reliability that industries depend on. By understanding the different types, from the robust QRC hydraulic coupling to a simple quick release coupling for water, you can optimize your operations for maximum efficiency.

When sourcing these critical parts, remember to consult a detailed QRC coupling catalogue and choose from reputable QRC coupling manufacturers who prioritize quality and performance. By making an informed choice, you ensure your systems run smoothly, safely, and without costly interruptions.

Frequently Asked Questions (FAQs)

1. What are the main types of QRC couplings?

The most common types include poppet valve, flat-face, and ball-type couplings. Flat-face couplings are ideal for preventing fluid spillage and contamination, while poppet-style couplings are a cost-effective general-purpose option. The best type depends entirely on the application’s specific requirements for pressure, fluid type, and environmental cleanliness.

2. How do I select the right material for my QRC couplings?

Material selection depends on the fluid being transferred, the operating pressure, and the environment. Carbon steel is common for hydraulic oil applications due to its strength. Stainless steel is preferred for corrosive fluids, water, or in hygienic environments like food processing. Brass offers good corrosion resistance and is often used for air and water lines.

3. What is interchangeability and why is it important?

Interchangeability refers to a coupling’s ability to connect with components from different manufacturers that are built to the same industry standard (e.g., ISO 7241-A or ISO 16028). This is important because it gives you flexibility in sourcing and replacing parts, preventing you from being locked into a single supplier.

4. How do I properly maintain a quick connect coupling?

Proper maintenance involves keeping the coupling clean and free of debris, as dirt can damage seals and prevent a proper connection. Regularly inspect seals for wear or damage and replace them as needed. Using dust caps and plugs when the coupling is disconnected is a simple and effective way to prolong its life.

5. What is the difference between a hydraulic and a pneumatic QRC coupling?

The main difference is their design pressure and material. Hydraulic couplings are built to handle very high pressures (thousands of PSI) and are typically made of steel. Pneumatic couplings operate at much lower pressures for air lines and are often made from lighter materials like brass or plastic. Using a pneumatic coupling in a hydraulic system is extremely dangerous and must be avoided.