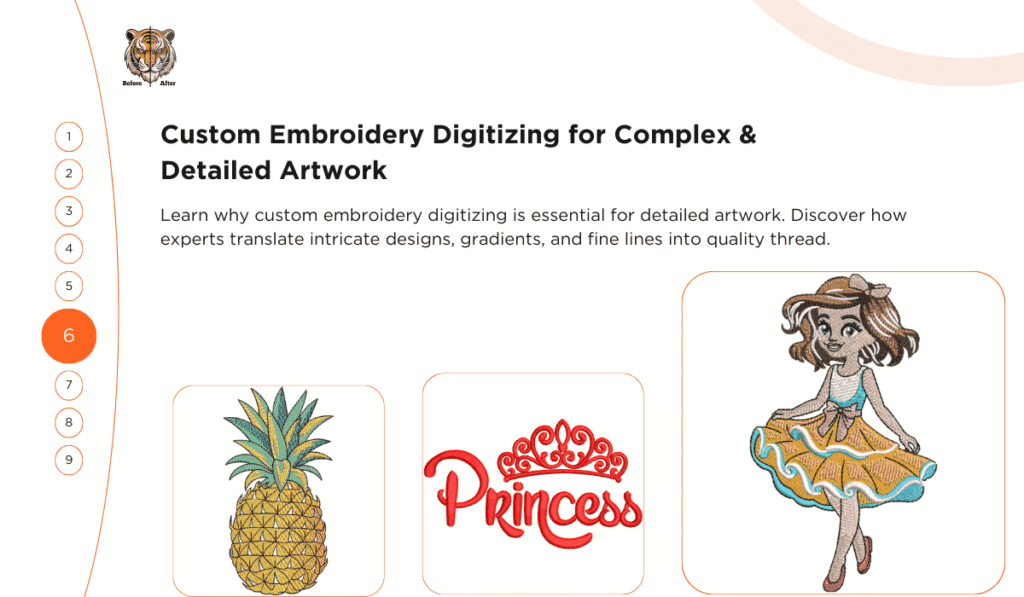

Not all designs are created equal. While simple text and bold shapes are common in embroidery, there is a growing demand for converting intricate, detailed artwork into thread. This includes everything from photorealistic portraits and detailed landscapes to complex brand logos with fine lines and gradients. For these projects, the standard approach to digitizing is insufficient. This is where the specialized craft of custom embroidery digitizing becomes absolutely necessary.

The core challenge lies in translation. A digital image is made of pixels that can be infinitesimally small. Embroidery is made of physical thread that has a fixed thickness. Attempting to replicate every minute detail of a complex drawing with thread is a recipe for failure. It results in a dense, muddy, and unrecognizable design. A skilled digitizer, however, does not just convert a file; they interpret the art. They make conscious, artistic decisions to preserve the essence of the design while respecting the physical limitations of the medium.

We will explore how this manual, expert-driven process is the only way to successfully transform complex artwork into high-quality embroidered pieces.

The Challenge of Translating Detail into Thread

The first hurdle in digitizing detailed artwork is managing what can be called “physical resolution.” A standard 40-weight embroidery thread is about 0.4mm thick. This means any detail in your artwork smaller than that is physically impossible to render with a single stitch. Automated software cannot comprehend this limitation. It tries to place stitches for every pixel it detects, which leads to an over-saturation of thread, causing needle breaks, fabric tearing, and a design that looks like a dense blob.

Custom embroidery digitizing involves a human expert analyzing the artwork and deciding which details are critical and which can be simplified or implied. They understand that trying to stitch every single leaf on a tree is less effective than using stitch direction and texture to create the impression of a full, leafy branch. This selective editing is an artistic judgment that software cannot perform.

Artistic Interpretation vs. Literal Conversion

A custom digitizer acts as an interpreter, not a photocopier. Their job is to capture the spirit and feel of the artwork, not to create a one-to-one stitch replica. This involves choosing the right stitch type for each element to convey texture and form.

For example, a smooth sky might be rendered with a flat “tatami” fill. The fur on an animal might be created using a “blended” fill with varying stitch angles to mimic the direction of hair growth. Fine lines from a pen sketch might be recreated using a light “running stitch.” A human digitizer combines these different techniques within a single design to build layers of texture and depth. This thoughtful combination of stitch types is what makes the final piece look intentional and professional, rather than machine-generated.

Managing Color Complexity and Shading

Complex artwork often relies on subtle color blending, shading, and gradients to create depth. Since you cannot mix thread like paint, a digitizer must use advanced techniques to create these effects. The most common method is “color blending,” where two or more solid-colored threads are layered with varying densities.

In custom embroidery digitizing, this is a manual process. The digitizer will plot the first color with a low density, then strategically place stitches of the second color on top. Where the stitches overlap, the eye perceives a new, blended color. It takes immense skill to do this without making the embroidered area too stiff or causing registration issues. An expert knows how to balance the stitch count to achieve the visual effect while keeping the garment comfortable and the production process smooth.

Preserving Legibility in Micro-Text and Fine Lines

Intricate artwork often includes small signatures, dates, or other fine details that are essential to the piece. These are frequently the first casualties of poor digitizing. A standard automated process will turn these details into illegible specks.

A custom digitizer will give these elements special attention. They may recommend using a thinner, 60-weight thread to allow for greater precision. They will manually adjust the structure of small letters, widening the gaps and simplifying serifs to ensure they are readable. For fine line art, they will trace the lines with a precise running stitch, carefully controlling the stitch length to create smooth curves rather than jagged, polygonal lines. This painstaking work is what preserves the delicate components of the original art.

Conclusion

Translating complex and detailed artwork into embroidery is a sophisticated process that automation simply cannot handle. It requires the eye of an artist and the precision of an engineer. Custom embroidery digitizing is the critical bridge between your creative vision and a tangible, high-quality finished product.

By making deliberate choices about simplification, texture, color blending, and fine details, a skilled digitizer ensures that the embroidered piece is a faithful and beautiful representation of the original artwork. For anyone unwilling to compromise on the integrity of their design, investing in this expert service is the only path to success.

FAQs

Q: Can any detailed design be embroidered successfully?

Not always. Sometimes, a design is simply too complex for the medium. A professional digitizer will provide an honest assessment and may suggest simplifications to ensure a good result. It is a collaborative process.

Q: Why does my detailed embroidery look messy and hard?

This is usually a sign of excessive stitch density. It means the digitizer (or software) tried to pack too many stitches into a small area to capture detail, resulting in a stiff, “bulletproof” patch where the details are lost.

Q: Can you embroider a photograph?

Yes, this is a highly specialized technique called “photorealistic digitizing.” It uses thousands of running stitches in many colors to mimic the pixels of a photo. It works best on large back patches and is not suitable for all designs or fabrics.

Q: How much detail is lost during the custom digitizing process?

Some simplification is always necessary. The goal is not to lose detail, but to interpret it effectively for the medium of thread. A good digitizer preserves the overall impression and character of the artwork, even if some microscopic lines are combined or simplified.

Q: Why can’t I just resize a detailed embroidery file?

Embroidery files are not like images. The stitch properties—density, length, and underlay—are calculated for a specific size. Shrinking the file makes the stitches too dense, and enlarging it creates gaps. Each size requires its own custom-digitized file.